Description

1、 Product Introduction

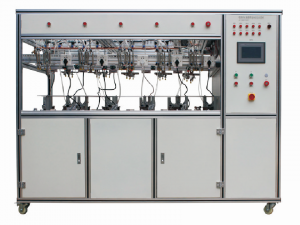

The comprehensive performance testing system for gas stoves is developed using imported sensors, flow meters, high-quality domestic components, and advanced software system testing technology, which fully complies with GB/T30720-2014 GB16410-2007 GB16411-2008. Mainly used for testing the thermal performance, smoke composition and temperature, and thermal radiation of gas stoves. Using the current industry’s lightweight automatic mixer for easy installation and use (No. ZL 2013 20824966.8).

2、 Product features

1. The on-off of gas is controlled by solenoid valves;

2. Using high testing components to collect various test data, and displaying it through the human-machine interface of the system, ensuring reliable, accurate, convenient, and intuitive reading;

3. Suitable for detecting desktop and embedded stoves, with adjustable installation holes for embedded stoves;

4. Using a computer control system to monitor the parameters during the testing process, including water temperature, gas consumption, gas temperature, gas pressure, ambient temperature, atmospheric pressure, and flue gas temperature

Automatically collect and calculate test results such as heat load and thermal efficiency;

5. The software automatically generates a testing database for easy querying and recording;

6. The system configuration is matched with the communication interface of the flue gas composition analyzer and thermal radiation acquisition instrument, and the thermal radiation related parameters of the flue gas composition can be automatically saved in the data management system,

Systematically analyze the combustion efficiency of stoves (this system can be connected to smoke composition analyzers and thermal radiation collectors, customers can choose to configure it themselves);

7. Using an automatic control mixing mechanical device to stir the test water in the pot, in order to achieve uniformity of water temperature;

8. The test bench has an adjustable air inlet to adjust the combustion air when detecting embedded stoves;

9. Configure various specifications of smoke sampling fixtures and thermal radiation sampling fixtures, suitable for testing pots of various specifications (optional);

10. Adopting a self-developed temperature sensor detector (No. ZL 2012 2 0009498.4) to achieve a transmission rate that is completely consistent with the national standard;

11. Through repeated verification and comparison by multiple authoritative institutions, with high repeatability and reliability;

12. Can be equipped with a gas automatic constant temperature control system.

3、 Technical parameters

1. Working power supply: AC 220V ± 10%, 50Hz;

2. Gas pressure test: 100-5000Pa, ± 0.5% F.S;

3. Gas temperature test: 0-50 ℃, ± 0.5% F.S;

4. Water temperature test: 0-100 ℃, ± 0.5% F.S;

5. Gas flow meter: 0-1200L/h, ± 0.3% F.S;

6. Smoke temperature test: 0-800 ℃, ± 1.5% F.S;

7. Environmental temperature test: 0-50 ℃, ± 0.5% F.S;

8. Atmospheric pressure test: 0-200kPa, ± 0.5% F.S;

4、 Test items

1) Thermal efficiency testing

2) Heat load test (measured heat load, converted heat load)

3) Heat load accuracy

4) Gas pressure test

5) Gas temperature test

6) Gas flow test

7) Water temperature (initial temperature, real-time monitoring temperature, final temperature) test

8) Air tightness testing (equipped with an air tightness tester) (optional item)

9) Combustion noise and stalling noise (equipped with sound level meter and optional items)

10) Smoke analysis (equipped with smoke analyzer and optional items)

11) Electrical performance test (equipped with electrical parameter table and optional items)

12) Environmental temperature. Radiation temperature test (testing angle)

Reviews

There are no reviews yet.